Shoreline Recovery and Protection Systems

Custom-Engineered Beach and Shoreline Composite Systems

100% Rust free

100% Custom design for each project

- Made from durable, rust and corrosion-resistant basalt and carbon fiber composites

- Lightweight for easy transportation, handling, and rapid installation

- Ideal for beaches, shorelines, waterways, canals, detention ponds

- Low long-term costs

Fifteen percent (15%) of the global population lives within a few miles of a coast—and the number is growing rapidly. As sea levels rise, shoreline erosion accelerates, seemingly uncontrollably. Yet, there are very viable solutions.

These pictures show a 17-year progression from an out-of-control situation to a state of nature in balance.

The recovery process starts with careful assessment, followed by a design phase. Permitting and approvals then follow, and finally the system is installed.

Given time and with the proper application of non-toxic, minimally invasive basalt-based technology, beaches can be recovered. Coastal erosion can be contained.

Common Applications

Ideal to use when natural, long-lasting, non-rusting, high-performance, corrosion-resistant infrastructure is desired

Coastline Recovery & Protection

Replacement of Aging Wooden, Concrete, or Steel Structures

Replacement of existing hard structures currently causing erosion (jetties, T-groins, armoring structures)

New Installations – custom engineered

Industry Challenges

- Nourishment projects fail if not properly stabilized

- Plastics, steel, and wood decay and fail over time

- Plastics and steel are environmentally unstable

- High maintenance costs and frequent repairs for traditional materials

Material Advantages

Composite Shoreline Recovery and Protection Systems overcome common issues, providing the perfect solution

- Non-corrosive in water

- Non-rusting & non-toxic

- Compatible with marine life

- Sustainable & recyclable

- Non-conductive

- Plentiful & lasts for generations

Business Benefits

EROSION CONTROL AND FUTURE COST AVOIDANCE

- Seawall repair/replacement

- Provides longevity to existing nourishment projects

- Emergency sand replenishment

- Infrastructure damage

- Increased project flexibility – custom engineering adapts to unique site conditions and requirements

- Improved ROI – long-lasting, resilient infrastructure supports long-term planning and budgeting

- Litigation (if property is lost or unsafe)

TOURISM USE & VALUE - WIDER BEACHES & STABLE WATERWAYS BRING INCREASED REVENUE FOR

- Hotels, rentals, and recreation

- Enjoyability Index

- Public use (city tax base increase)

Product Offerings

Beach Recovery System

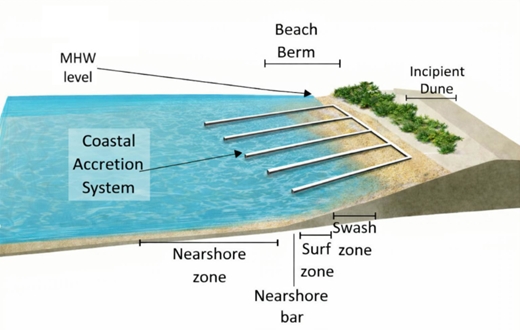

- Coastal Accretion Designs (CAD) are implemented to stop erosion and restore your shore.

- Naturally regenerates lost land, restoring your shore.

- Long-lasting & environmentally compatible.

- Works with nature leading to habitat return.

- Proven track record – 40 years of results.

- Very low maintenance.

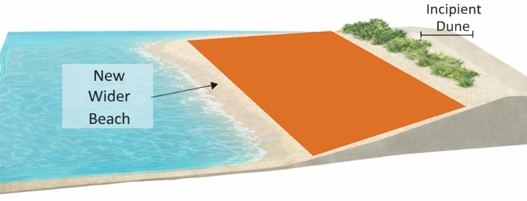

An eroded beach has no room for towels and zero tourist value. It is an unusable beach that fails to protect real estate assets and the overall ecosystem.

Our beach recovery process starts with an extensive scientific review of multiple aspects of the existing environment. A fully customized and site-specific natural basalt-based coastal accretion system is built and installed.

During wave action, excess sand is suspended in the water. As the water slows, coarse grains settle first, followed by finer grains. Each wave cycle creates thin layers of deposited sand.

Over days to weeks, these layers accumulate, forming a wider berm, a gentler beach face, and sometimes buried storm layers. The system itself gets buried. The beach is recovered.

The nourishment doesn’t remain simply because it was placed; it persists because it is repeatedly re-deposited into stable layers through ongoing wave action and settling. This is the key difference between our approach and simply mass-depositing sand from barges.

The recovered wider beach provides long-lasting protection of real estate assets, helps restore the ecosystem, and fisheries. It also buffers the environment from future storms and sea-level rise.

Wider beaches are revenue making. A recovered beach bring tourists, towels on beaches and safer swimming conditions. They support hotels, rentals, and recreation, and support public use and preserves the city tax base. Contact us to learn more.

Sea Wall

- Our Seawall does not rot or rust and doesn't require cathodic protection as compared to conventional wood and metal seawall materials.

- Our proprietary Basalt FRP composite sheet piling products are sustainably produced.

- These are more durable, corrosion-resistant and eco-friendly seawalls.

- We manufacture UV-resistant, lighter weight and greener alternatives, reducing shipping and handling costs, and carbon footprint.

- We want you to build it once and reduce ecological impact and long-term protection.

- Our high-strength military-specification formulation was DESIGNED, TESTED AND ACCEPTED in collaboration with the US Army Corps of Engineers

Contact an Expert

Please contact us if you have any questions about our products. One of our experts will get back to you as soon as possible.

Contact Us NowStart a Quote

To begin the purchase process, click below and answer a few preliminary questions. We'll get back to you with more information as soon as possible.

Start Quote